To make a chairs godown, first, pick the right location! You want it near transportation hubs so moving chairs is a breeze. Next, design a smart layout that uses vertical space—it’s like stacking Jenga blocks but safer! Don’t forget shelving systems; think durable materials and maybe even tech like pick-to-light. Finally, guarantee you have exceptional security to protect your treasures. Excited to learn more on how to optimize your setup? Let’s keep building!

Key Takeaways

- Conduct thorough cost analysis and market research to select an affordable location for your chairs godown.

- Choose a site near transportation hubs for convenient access and efficient shipping logistics.

- Design the warehouse layout to optimize space and minimize movement, incorporating vertical storage solutions.

- Implement strong security measures, like surveillance systems and access controls, to protect your inventory.

- Estimate storage capacity accurately by measuring space and considering vertical stacking for efficiency.

Selecting the Ideal Location for Your Chairs Godown

When you’re setting up a chairs godown, choosing the right location is super important! You’ve got to think about cost analysis and do some market research. Is the land affordable? Remember, shipping costs can eat into profits if you’re too far from your customers!

You’ll also want to be near transportation hubs. Can trucks easily access your site? A central location saves time and boosts customer satisfaction! Plus, consider the labor market. Is there a pool of skilled workers nearby?

Don’t forget about compliance, either. Are there zoning laws you need to follow? It’s better to be proactive rather than deal with legal headaches later! Finding that sweet spot takes time, but it’ll be worth it in the end! Additionally, ensure your location has good safety features to protect your inventory from potential damages.

Designing the Warehouse Structure for Efficient Operations

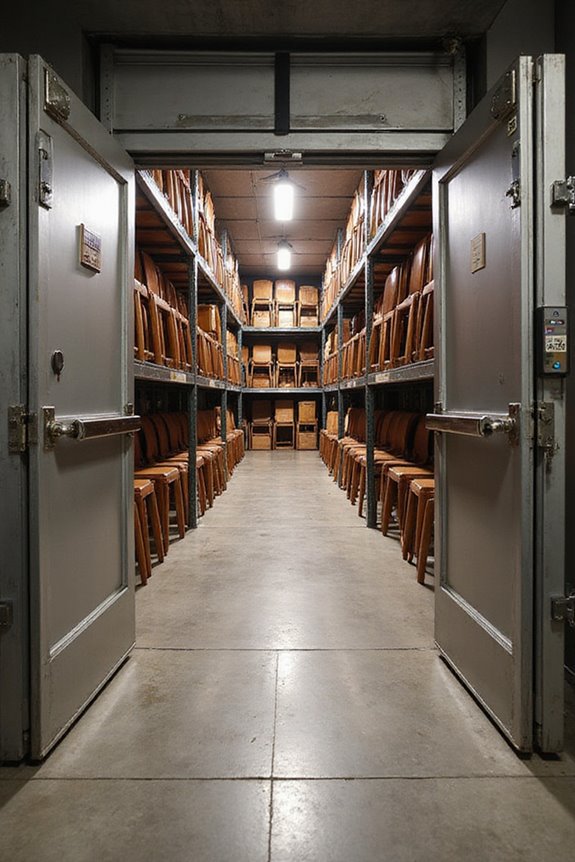

Designing the warehouse structure for your chairs godown can feel like a puzzle, but figuring it out is essential for smooth operations. Start by mapping out an efficient warehouse layout. You want a flow that minimizes the time it takes to move your chairs, right? Consider using vertical space to maximize storage. High-density racking can help you fit more without taking up extra floor space!

Don’t forget about flexibility; keeping equipment accessible can save you from unnecessary hassles during busy days. Plan for future growth too—nobody wants to redesign later! And remember, safety is key; guarantee easy movement for both people and equipment, so everyone can work efficiently. Storage ottomans can also serve as a clever way to organize smaller items within the warehouse. Ready to plunge into your design? Let’s get to it!

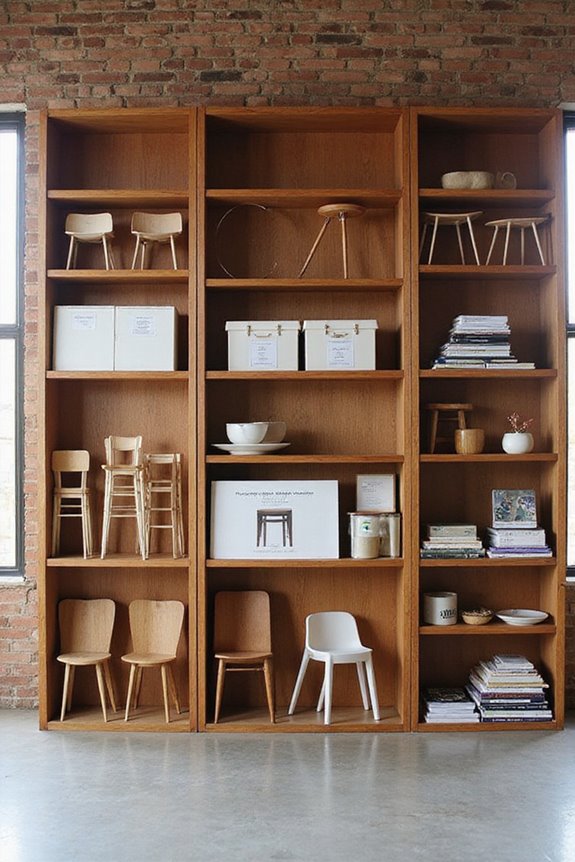

Implementing an Effective Shelving System

Implementing an effective shelving system is essential for getting your chairs organized and easily accessible. Have you considered the various shelving types? Selective racking offers low costs and easy access for every chair. Or, if you’re tight on space, push-back racking can save you room while still giving you selectivity!

You’ll want to think about your inventory management too. Where do you store heavy or frequently-used chairs? Proper item placement and clear labeling make a huge difference. Plus, incorporating technology like pick-to-light systems can boost your picking speed. Additionally, using high-quality materials for your shelving can enhance durability and support.

Don’t forget about safety! Regularly inspecting your shelving guarantees everything stays in good shape. So, ready to create a chair haven that’s both functional and fun? Let’s do this!

Ensuring Robust Security Features

Securing your chair godown isn’t just about keeping up appearances—it’s about creating a safe haven for your valuable inventory! First up, you need robust surveillance systems. Install security cameras at all entry points and high-value storage areas. Don’t forget those night vision features—who wants to miss a thing after dark?

Now, let’s chat about access control. You want to keep it strict! Use key cards or maybe even biometric scanners to limit entry to authorized folks only. Tracking who goes in and out? Super important!

With these features, you can rest easy knowing your inventory is safe. Are you ready to step up your security game? Let’s make your godown a fortress!

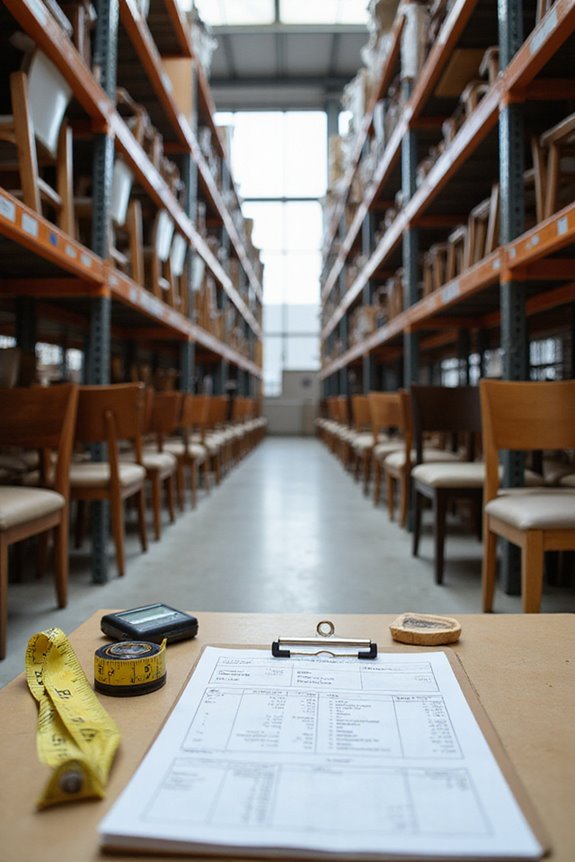

Estimating Storage Capacity Accurately

When it comes to making your chair godown work for you, accurately estimating storage capacity is key! Start by measuring square footage for your space; it gives you a solid baseline. Don’t forget to convert all measurements to the same unit—trust me, it’ll save headaches later. Have you identified non-storage areas like offices? Subtract them to find usable space!

Next, contemplate optimizing your layout. How much vertical space can you stack safely? Between pallet sizes and stacking heights, there’s a lot to take into account. With a solid plan, you can even set those utilization goals to guarantee no space goes to waste. So, are you ready to calculate dimensions and maximize that storage efficiency? Let’s go!

Establishing Quality Assurance Strategies

With your storage capacity all figured out, it’s time to shift gears and focus on quality assurance strategies! Ever thought about how vital those quality standards are? Start by inspecting raw materials for defects—no one wants a wobbly chair! You should establish strong inspection protocols, checking for cracks or warping, to guarantee durability.

Don’t forget to document everything; after all, traceability is key! Implement visually engaging SOPs that your team can easily follow. Make certain everyone knows their roles—who’s checking materials and who’s testing the final product? And what about regular training sessions? Keeping your crew sharp on inspection protocols can make a real difference. Let’s face it, nobody enjoys sitting on shaky furniture! Keep those chairs godown-worthy!

Prioritizing Staff and Operations Safety

While you might be all geared up to create those godown-worthy chairs, have you ever considered the safety of your team and operations? It’s essential to follow safety protocols. For starters, guarantee that workers handling equipment are certified. Think about it! Wouldn’t you want your team to feel confident and secure?

Also, regular safety training is a must. Teaching hazard recognition can help minimize accidents during daily operations. Don’t forget about emergency procedures! Your staff should know how to act quickly when something goes wrong.

Plus, keeping storage areas clean and properly labeling hazardous materials can prevent mishaps. Remember, a safe workspace fosters creativity and productivity. So, prioritize safety, and watch that creative spark fly! Isn’t that worth it?

Frequently Asked Questions

What Are the Typical Lead Times for Chair Manufacturing?

You’ll discover that typical lead times for chair manufacturing can vary dramatically. Unexpected lead time factors, like supply chain disruptions and manufacturing processes, will keep you guessing, with standard waits ranging from 2 to 6 weeks.

How Do I Choose the Right Type of Foam for Chairs?

To choose the right foam for chairs, consider foam density and your desired comfort level. Higher densities provide better support and longevity, while firmness affects overall comfort. Prioritize your specific needs and usage when selecting.

What Certifications Are Necessary for Chair Manufacturing?

When considering chair manufacturing, you’ll need certifications like ISO 9001 for quality standards and ISO 45001 for health safety. Adhering to industry regulations guarantees your products are safe, durable, and environmentally responsible.

How Can I Optimize Space in a Small Chairs Godown?

Oh, because there’s nothing more thrilling than cramming chairs into a tight space! Use vertical storage and multi-functional furniture to maximize every inch. It’s all about making your small godown feel like a spacious wonderland!

What Common Materials Are Used in Chair Upholstery?

When exploring fabric types for chair upholstery, consider natural materials like cotton and wool, or synthetics like polyester and microfiber. Utilizing various upholstery techniques can enhance both durability and aesthetic appeal of your seating.